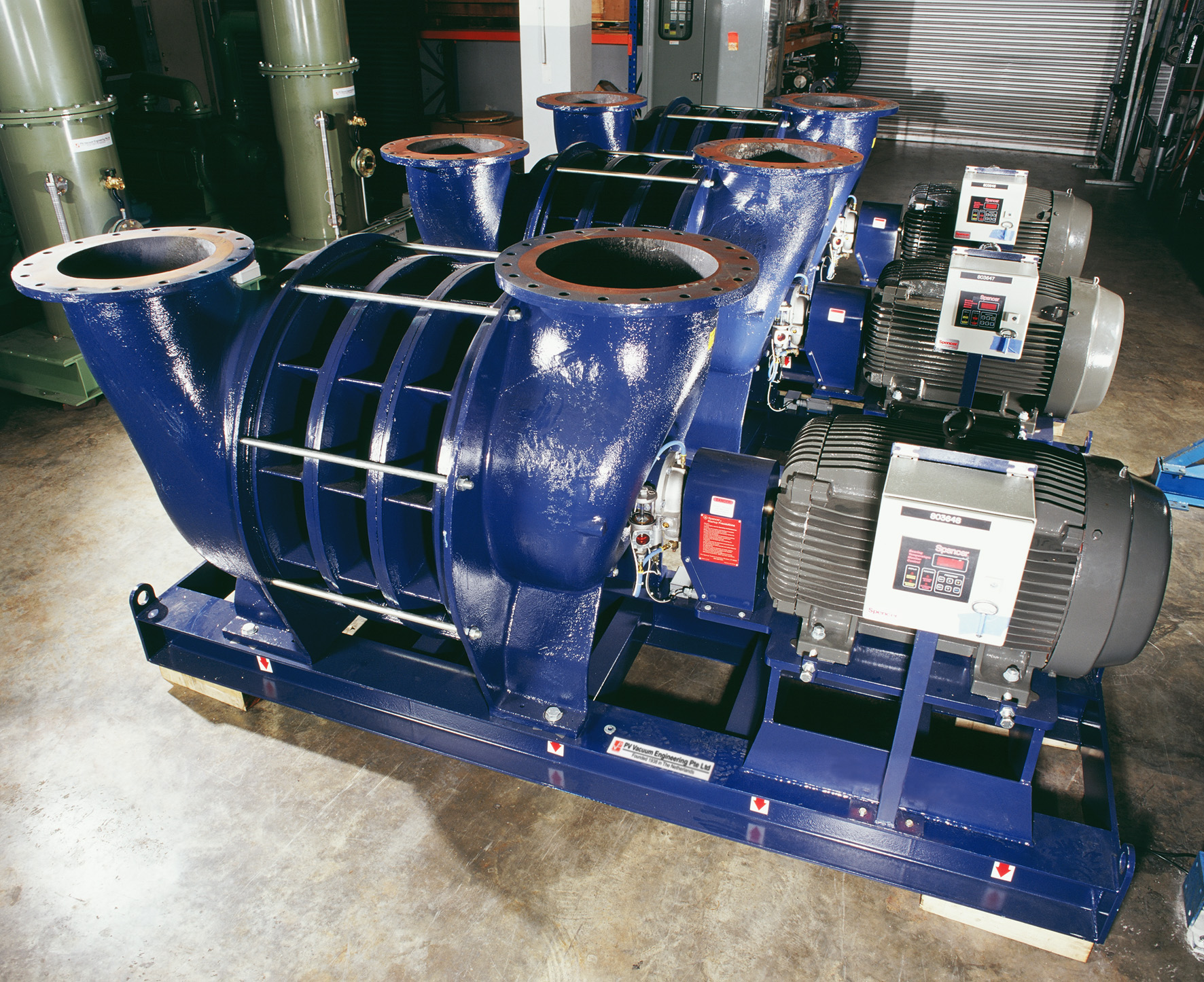

The Central Vacuum Producing Plant

Vacuum Exhauster

All systems are unique and are highly specialized in its target applications. At PV, we provide vacuum exhauster that could deal with most difficult applications, including:

- Corrosive & Toxic gases such as sulfides, halogens, acids, flue and stack gases, cyanides and ammonia.

- Temperatures to 1100 Deg F.

- Casing Design Pressures to 1000 PSIG

- Differential Pressures to 20 PSIG

- Highly restrictive shaft sealing or gas-tight requirement - allowing toxic or harmful gas/material to be kept within the system.

- Vibration level comply to Class B - Classes Microelectronics Manufacturing Equipment.

Custom metals and coatings

Scores of metals and coatings are available for customized performance. PV has the sheet steel fabrications capability to provide you with such flexibility to have machine built to suit your applications.

Surge Prevention

Surge is a situation that happens to vacuum exhauster when there is not enough demand from production. An Electronic Modulating Bleed Device is the option that we provide to over-come this problem during low system usage condition.

The device automatically monitors the inlet condition of the vacuum exhauster and compensates it accordingly to prevent a surge condition from happening. The system does not need to be sized to cater for any additional air flow requirement unlike normal Bleed in Device. A great way to save energy in operation.